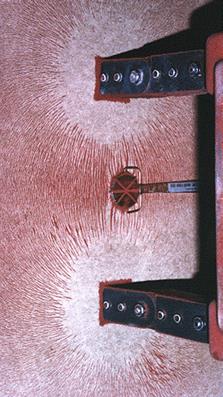

Electromagnetic Yokes (MF)

Electromagnetic yokes or electromagnets require a source of electrical energy which may be A.C. or D.C. This is also a specific technique used on the bench equipment to generate a longitudinal magnetic field employing two coils/ solenoids within the headstocks.

The yoke is made from highly permeable, low retentive steel, which is laminated to reduce induction caused by eddy current flow (associated only with alternating current) this also helps to prevent the yoke becoming permanently magnetised.

Magnetism is induced into the yoke by encircling it with a coil through which a current is passed, the strength of the field produced can be varied in one of two ways:

- By adjusting the current (amperage) flowing through the yoke - electromagnets allow for this. only certain

- By varying the distance between the pole pieces - most electromagnets allow for this but not all. Note: The strength of the field is varied from pole to pole, regardless of the comments above, as the flux is concentrated at the yokes poles upon entering the component.

In accordance with BS EN ISO 9934-1, the field strength available from the equipment may be determined via either:

- Practically testing an example object with either a natural or artificial flaw.

- Measuring the tangential field strength as close to the surface as possible. (Note: permanent and D.C. electromagnets are not recommended for use in this standard.)

- BS EN ISO 9934-3 requires the above or a lift test of 4.5 kg or a 500 x 250 x 10 mm plate using the tangential field strength meter to measure the field strength.

The old BS 6072 stated for ac yokes a lift test of 4.5 kg and a pull off test of 2.25 kg for a pole spacing of 300 mm or less, dc yokes had the same requirements as permanent magnets.

Electromagnets may operate direct from the mains supply of 240V but are available at 110V (battery packs are now available at 12/ 24/ 36V for more flexibility) when required for site use. The field produced from an electromagnetic yoke is longitudinal, travelling from pole to pole as with permanent magnets, however the depth of the field within the test piece will depend upon the type of current used to induce magnetism.

Surface discontinuities will be more readily found using AC. Sub-surface discontinuities will be more easily located using D.C. The magnet will have a much greater pull on DC, but the flux will be less at the surface of the component being tested.

BS EN ISO 9934-1 states the testing area shall not be greater than that defined by a circle inscribed between the pole pieces and shall exclude the zone immediately adjacent to the poles. It also states the area adjacent of the poles (typically 25 mm) should be ignored.

Advantages of electromagnetic yokes include:

- A.C. or rectified D.C. operation.

- Controllable field strength (not in all cases).

- Can be switched on/off as required.

- No damage done to test piece.

- Relatively lightweight.

- A.C. yokes may employ the wiper brush technique for demagnetisation.

Disadvantages include:

- Power supply required.

- Only small areas can be examined at each magnet location.

- Leaves only one hand free.

- D.C. yokes are not recommended to be used in conjunction with flux indicators.